Optimized for process and cost-of-ownership

All of the SOMOS IWT double-side, automated and custom production machines are engineered, designed and built for process and cost-of-ownership optimization.

In each case, several double-side machines can be integrated into the one process flow. This process flow can be sequenced with ultrasonic stations as well. Complete production lines thus allow all operations to be carried out in a fully automated manner.

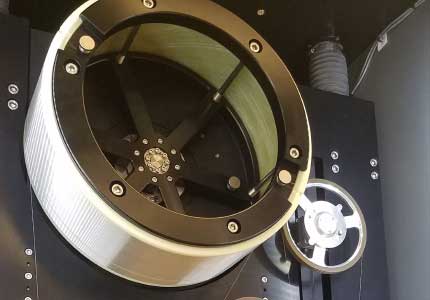

OA 400

Automated Production Line

- Automated single-side lap

- Cleaning

- Single-side polish

- Application: Precision Optics Components

TPM 400

Automated Production Line

- Double-side lap

- Ultrasonic clean

- Double-side polish

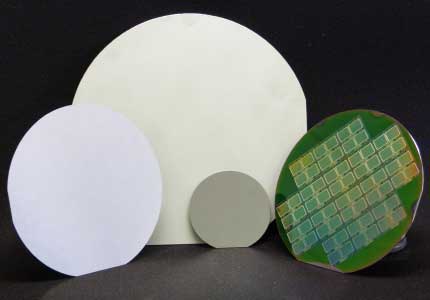

- Application: Production of planar precision optics components

TPM 630

Automated Production Line

- Double-side fine grinding

- Ultrasonic clean

- Double-side polish

- Application: Production of palnar ultra-precision optics components

MDF 5000C - Automated Production Line

Two fully automated cells - single-side and double-side lap and polish, cleaning and control system.

Application - Production of fuel injector parts at 140,000 units/day.