The single-side series

Overview

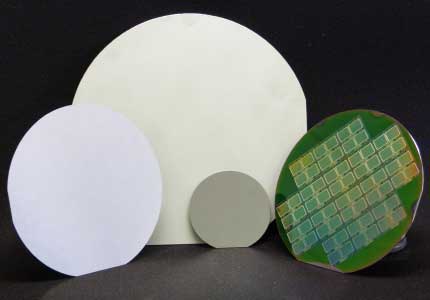

Single-sided machines are widely used in all traditional optical component lapping and polishing operations. The “Single flat face” equipment (for flat surfaces and large curvatures) and “Single spherical face” (for convex or concave shapes) allow high quality surfacing whatever the geometry of the parts. Machinery equipment and supplemental tools designed to meet growing industry demands for technologically advanced, reasonably priced high precision surfacing.

Features

- Broad range of applications

- Designed for specific applications

- Built with the same robust quality as our double-side machines

Benefits

- Meeting the current and future challenges of high precision surfacing

- SOMOS IWT can custom design the machine to your specific applications

R & RP Series

Open-face and pneumatic-assisted flat lapping and polishing machines from 320 to 2000 mm (12.5” to 6.5”) plate diameter. Virtually any material may be processed, including metals, glass, ceramics, crystals, etc.

The operating range is from 1 to 60mm (0.040” to 2.5” approx.) radius.

MPR Series

Oscillating-arm type, high-speed plane and spherical fine grinding, lapping and polishing machines. Suitable for virtually all materials.

Plate diameters from 250 to 1000mm (10” to 3.25’).

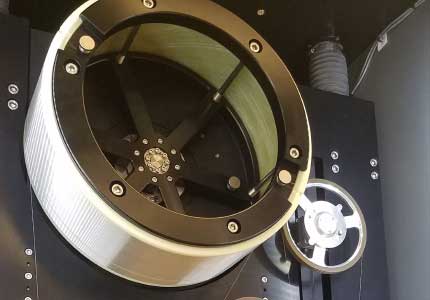

PC & SPM Series

Arm type high-speed spherical lapping and polishing machines for short-radius spherical surfaces, for optical glass and virtually all materials.

The operating range is from 1 to 60mm (0.040” to 2.5” approx.) radius.

OA Series

Articulated-arm type shown with intermittent cleaning station. Use for flat and spherical surfaces.

The principal application is lapping, polishing of precision optics using pads or pitch.

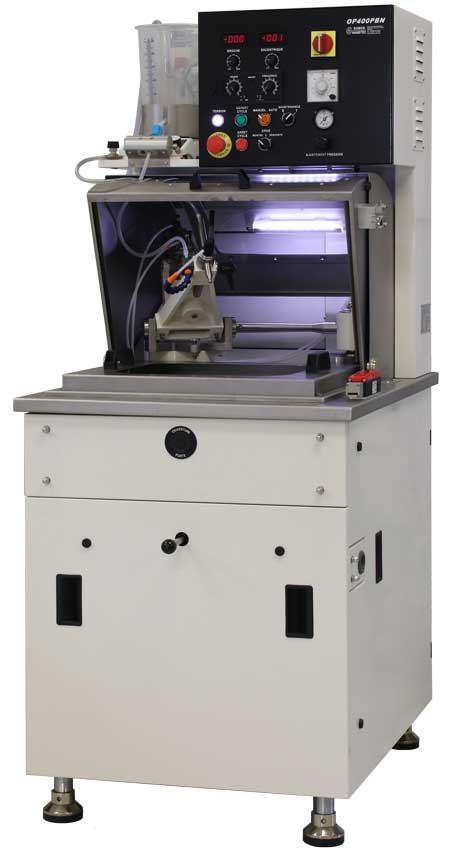

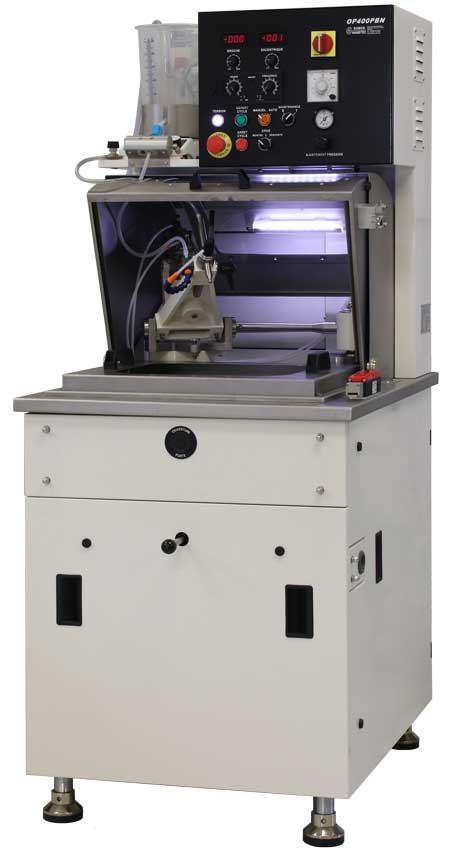

OP & OPY Series

Articulated-arm type lapping and polishing machines for flat and spherical surfaces, for optical components and virtually all materials.

The principle application is lapping and traditional polishing of optical components, using synthetic pads or pitch.

Tank diameters from 250 to 600mm (10” to 5.25’).